The 250KG ANFO kettle pressure vessel is a purpose-built mining ANFO kettle designed for the safe, controlled and compliant handling of ammonium nitrate fuel oil (ANFO) on mining and blasting sites. Engineered for industrial use, this ANFO pressure kettle provides reliable pressurisation and discharge performance while meeting Australian pressure vessel and hazard classification requirements.

With a 250kg capacity, this ANFO kettle pressure vessel is suited to high-volume blasting operations where consistent charge density, safety and operational efficiency are critical.

What Is an ANFO Kettle?

An ANFO kettle (also referred to as an ANFO pressure kettle) is a pressure-rated vessel used to pneumatically discharge bulk ANFO into blastholes. By using compressed air, ANFO can be placed accurately and consistently, helping to achieve predictable blast results and improved fragmentation.

The 250kg ANFO kettle is commonly used in underground mining, quarrying and civil blasting applications where dry blastholes are present and high throughput is required.

Pressure Rating & Hazard Classification

This ANFO kettle pressure vessel is manufactured and certified in accordance with Australian standards for unfired pressure equipment. The vessel is rated to 690 kPa at 55°C, ensuring safe operation under pressurised conditions commonly encountered during ANFO loading.

The pressure vessel complies with:

-

AS1210-2010 – Pressure Vessels

-

AS4343-2014 – Pressure Equipment – Hazard Levels

The vessel is classified as a class 1, Hazard Level C, confirming it meets the applicable safety, inspection and design requirements for its operating pressure, volume and service conditions.

WorkSafe Design Registration

The 250kg ANFO pressure kettle is supplied with WorkSafe Design Registration, providing formal confirmation that the pressure vessel design has been assessed and accepted by the relevant regulatory authority. This assists mining operators with compliance, engineering verification and safety audits.

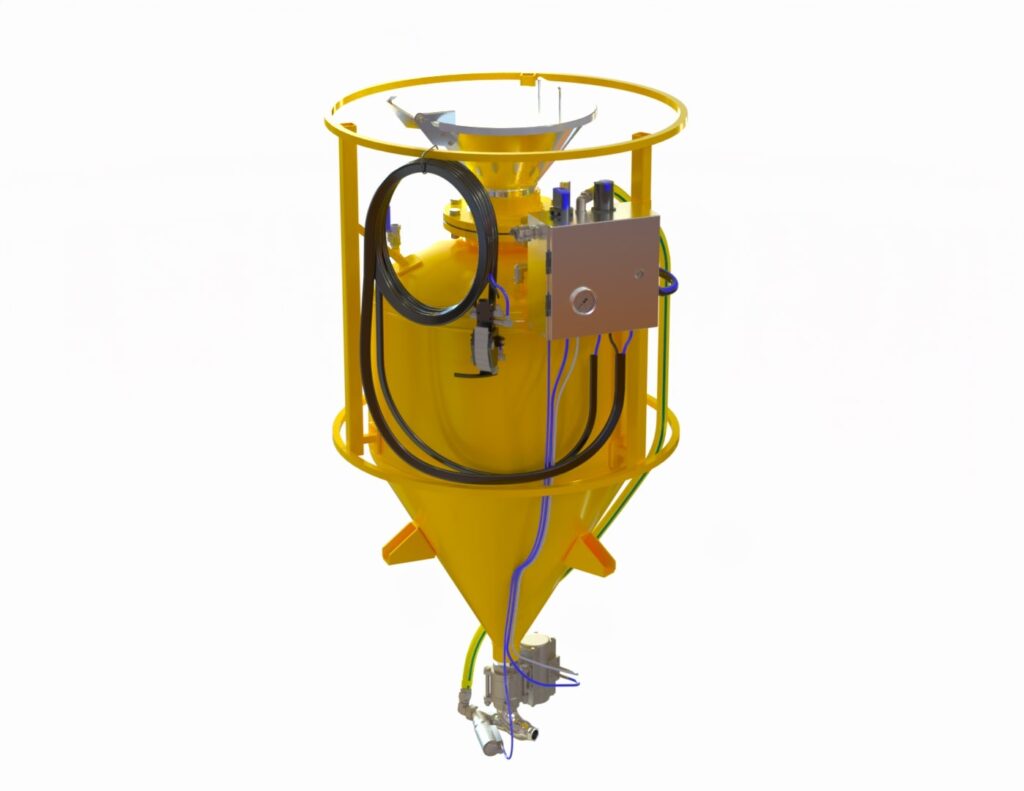

Construction & Design Features

Designed for harsh mining environments, the mining ANFO kettle features a robust pressure-rated body and industrial-grade components intended for repeated daily use. The vessel can be supplied as a standalone unit or integrated into a machine frame or handling basket, depending on site requirements.

Key design features include:

-

250kg ANFO capacity for high-volume blasting operations

-

690 kPa pressure rating at 55°C

-

Class 1, Hazard Level C pressure vessel

-

Stainless steel waterproof valving enclosure protecting controls

-

Colour-coded air supply and actuation system for operator clarity

-

Plug-and-play supply of valves, actuators and fittings for simplified installation

These features help reduce operator error, protect critical components and support consistent pneumatic loading performance.

Operational Benefits

Using a 250kg ANFO kettle pressure vessel allows blasting crews to maintain uniform charge density throughout the blasthole, which is essential for achieving consistent fragmentation and controlled blast outcomes. Pneumatic loading via an ANFO pressure kettle also reduces manual handling, improves loading speed and supports safer explosive placement.

The 250kg capacity offers an effective balance between productivity and practical site handling, making this mining ANFO kettle suitable for both mobile and fixed blasting setups.

Typical Applications

This ANFO kettle pressure vessel is suitable for use in:

-

Underground mining operations

-

Quarry blasting

-

Civil and infrastructure blasting projects

-

High-volume blasthole charging environments

When used in accordance with site procedures and explosive handling regulations, the ANFO pressure kettle integrates seamlessly into established blasting workflows.

Safety & Use Considerations

Operation of an ANFO kettle pressure vessel must be performed by trained personnel familiar with pressure equipment, pneumatic systems and explosive handling protocols. Routine inspection, correct pressurisation procedures and adherence to site safety systems are essential to maintaining compliance and safe operation.