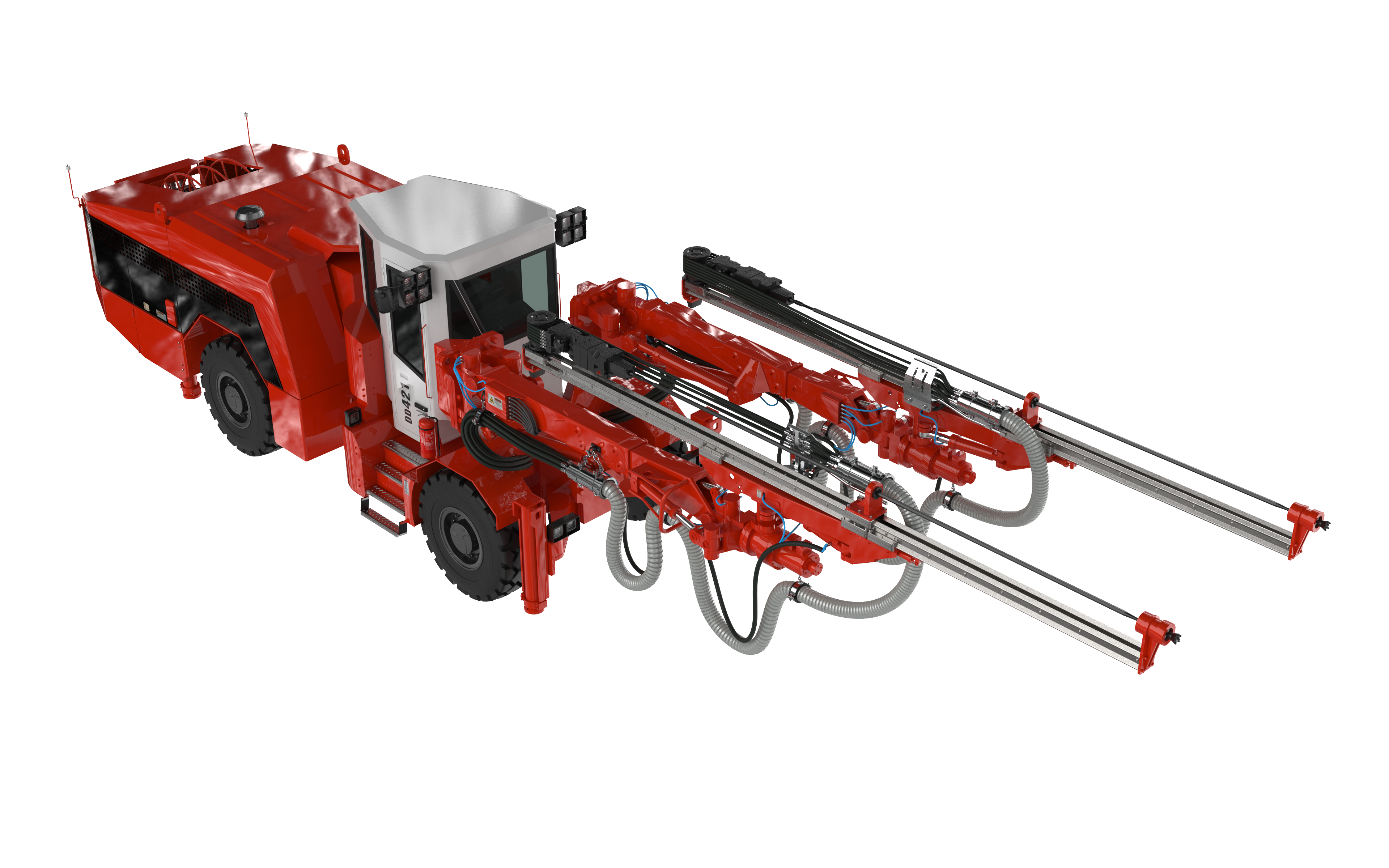

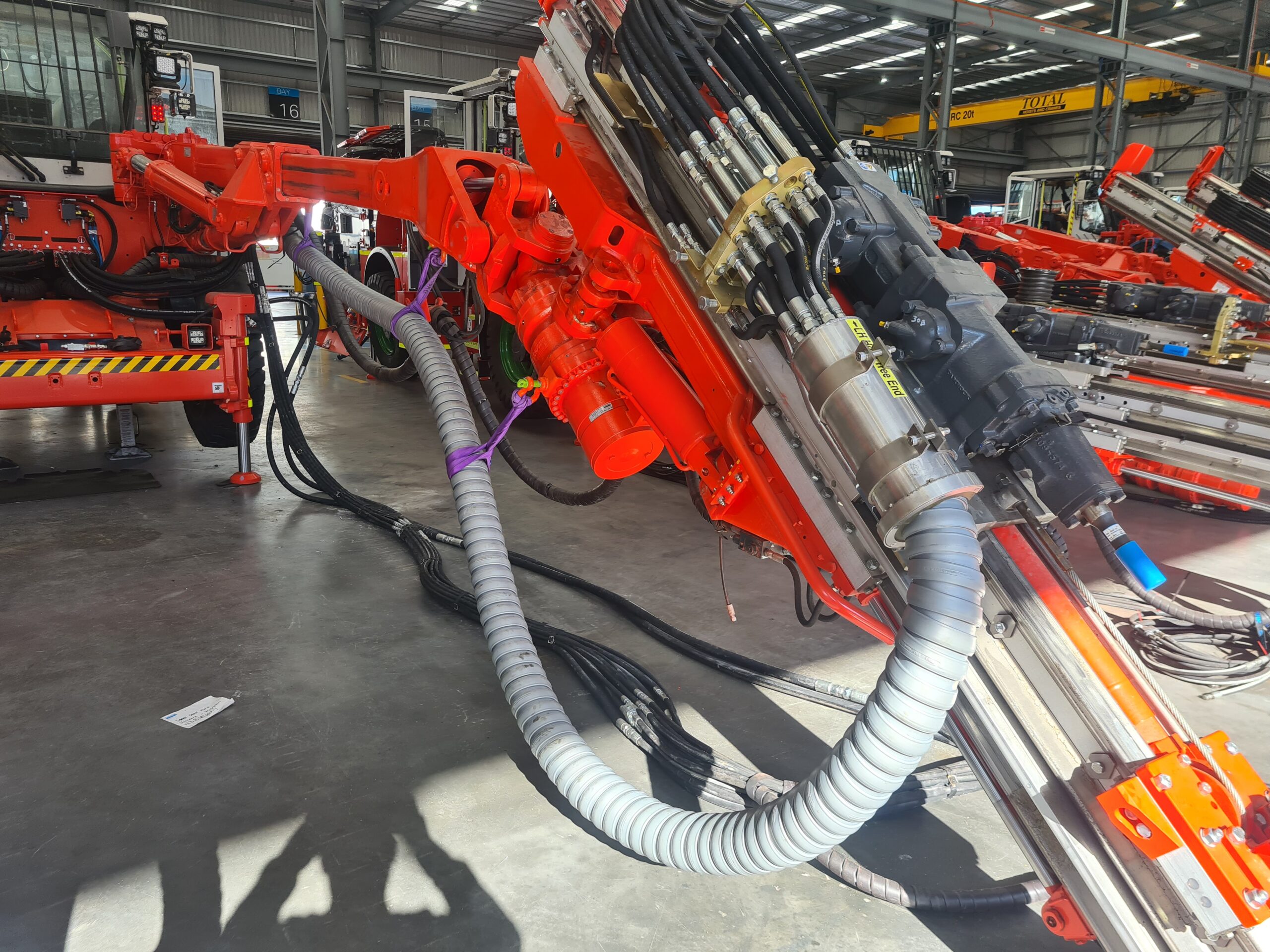

The EVALAST™ Hydraulic Loom is a custom-engineered solution designed for optimal longevity and maximum machine uptime in mining operations. With its innovative five-layer protection system, it offers unparalleled durability, efficiency, and peace of mind for hydraulic applications.

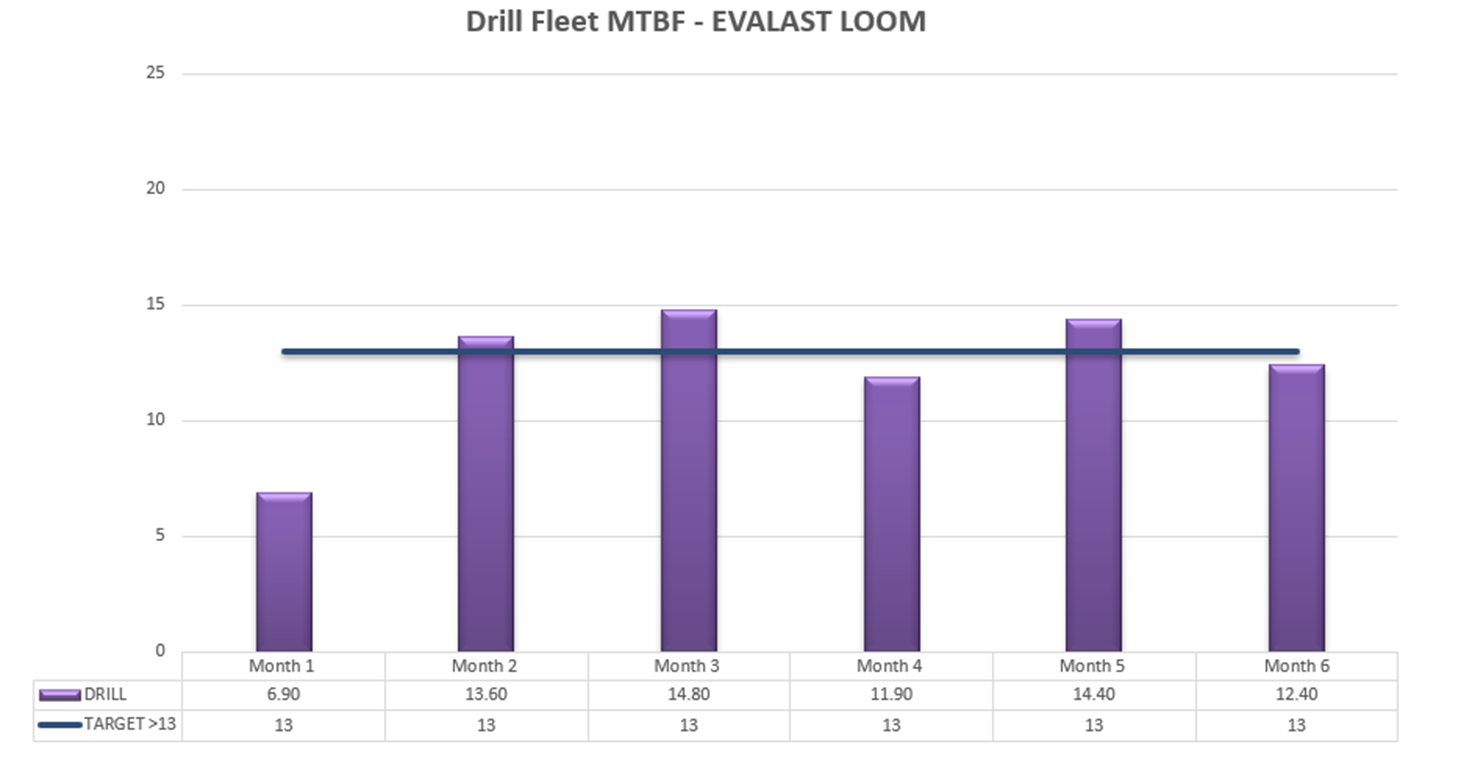

The EVALAST™ Hydraulic Loom does not only offer large direct Material cost saving. It offers increased development advancement due to less breakdowns, less service intervals and less time during servicing. Assuming a drill experiences six breakdown a month at two hours per breakdown, the EVALAST™ will gain every drill an additional 12 hours of drill time per month on Average.

- Five layers of protection for optimal longevity

- Kevlar Braid for superior strength

- MSHA approved burst protection

- Waterproof membrane

- Additional durable No-Gap wrap to protect from external impact.

- Stainless-steel end caps with internal sleeve locking mechanism

- Special binding material to prevent hose slapping internal in the end caps

- Impervious to common causes of hose failure (chafing, slapping, external impact)

- Individually tested to Australian and international standards